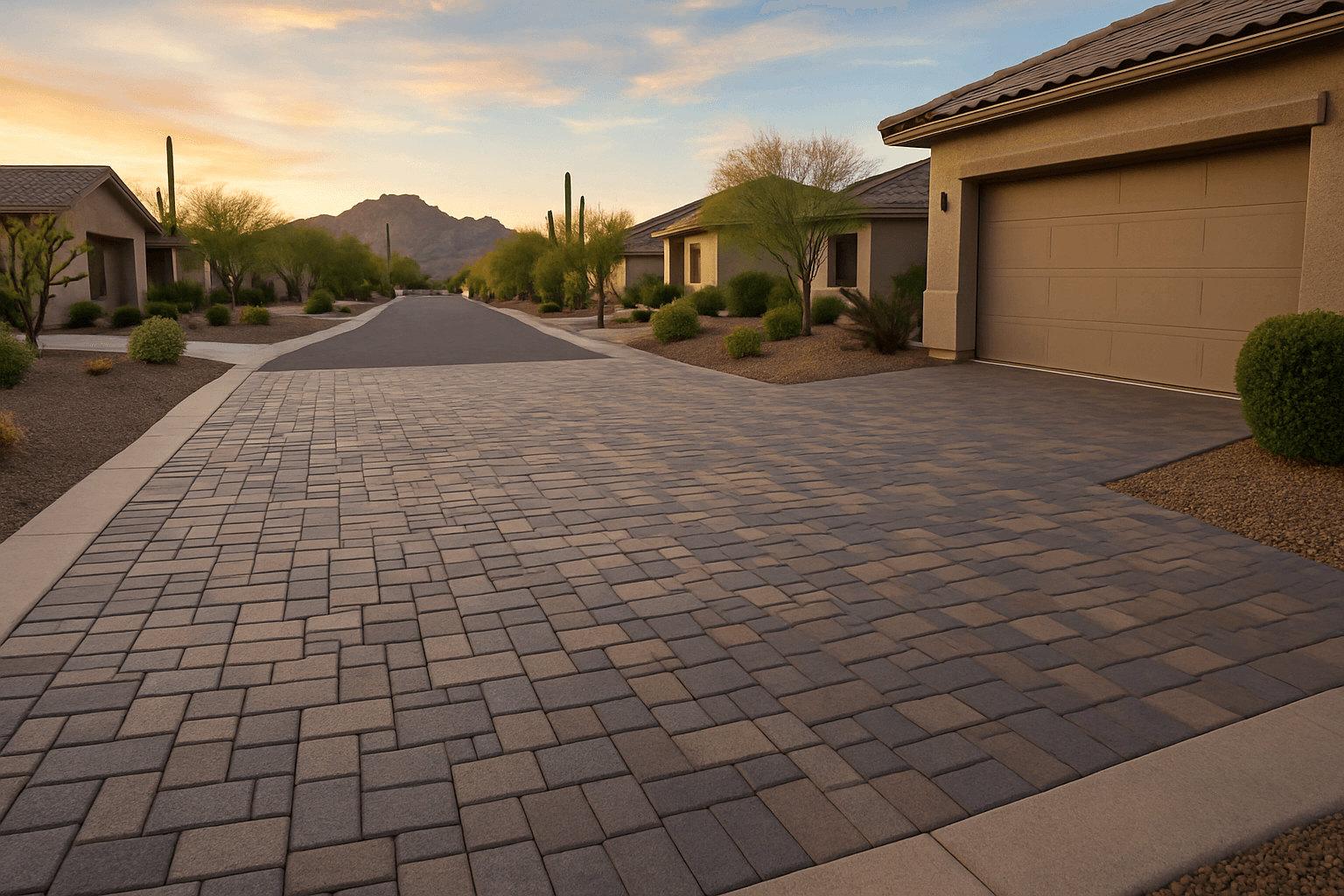

There is something genuinely satisfying about looking out at your backyard and seeing a perfectly leveled, beautifully patterned paver patio. It just feels… right. But getting to that point? That is a whole different story. Living here in Gilbert, we know that outdoor living is practically a mandatory part of the lifestyle. Whether it’s for those cooler winter evenings or a splash pad surround for the summer, a paved area changes how you use your home.

But here is the truth nobody likes to talk about: a lot of paver jobs fail. Not immediately, of course. They look great for a month or two. Then, the settling starts. A brick sinks here, a weed pops up there, and suddenly your expensive hardscape looks like a roller coaster. If you are thinking about upgrading your Driveway, walkway, or pool deck, understanding the mechanics of a successful Paver Installation is half the battle. You don’t need to be a structural engineer, but you do need to know what separates a twenty-year patio from a two-year disaster.

Contents

- 1 Before You Even Touch a Shovel

- 2 The Dig Out: It’s More Than Just Dirt

- 3 It’s All About That Base (Literally)

- 4 The Screeding Process

- 5 Laying the Pavers: The Fun Part

- 6 Keeping It Together: Edge Restraints

- 7 The Finishing Touches: Sand and Seal

- 8 Sealing: Is It Necessary?

- 9 Why Hiring a Pro Often Saves Money

- 10 Ready to Transform Your Yard?

Before You Even Touch a Shovel

Honestly, the physical work is the second half of the job. The first half happens in your head and on paper. You might be tempted to just run to the hardware store, grab a pallet of bricks, and start throwing them on the dirt. Please, for the sake of your wallet, don’t do that.

We have to deal with specific soil conditions here in the East Valley. We have clay, we have caliche, and we have soil that loves to expand when the monsoons hit.

The “Boring” But Crucial Prep Work

Before a single tool hits the ground, you need a plan. And I don’t just mean a sketch on a napkin (though that helps). You need to think about drainage. Water is the number one enemy of hardscapes. If you install pavers that slope toward your foundation, you are asking for water damage. The industry standard is usually a slope of about one-eighth to one-quarter inch per foot away from any structures.

And hey, don’t forget the red tape. In Gilbert, many of us live in HOA communities.

- Check your HOA guidelines: They might have restrictions on colors or percent of lot coverage.

- Call 811 (Blue Stake): This isn’t optional. You need to know where your gas, electric, and water lines are. Hitting a gas line is a quick way to ruin your week.

The Dig Out: It’s More Than Just Dirt

So, you are ready to break ground. This is where most DIYers—and even some inexperienced contractors—make their first major mistake. They don’t dig deep enough.

You can’t just scrape the Grass off and start building. You need to accommodate the paver thickness, the bedding sand, and the compacted base. Usually, for a standard patio, this means excavating about 7 to 9 inches down. If it’s a driveway holding heavy vehicles? You are going deeper.

It’s grueling work, especially when the Arizona ground fights back. But getting that organic soil out of there is non-negotiable. Organic soil decomposes and shifts over time. You want to get down to the sterile subsoil that isn’t going to change shape just because it rained.

It’s All About That Base (Literally)

If you take one thing away from this, let it be this: The pavers are just the icing; the base is the cake.

You could buy the most expensive, Italian-imported pavers in the world, but if they are sitting on a weak base, they will fail. Period. The base material is usually a crushed rock aggregate—often referred to as ABC (Aggregate Base Course) or “road base.” It’s a mix of ¾-inch rocks down to fine dust.

Why the Mix Matters

The different sizes of rock allow the material to lock together tightly, leaving no voids. When you pour this in, you don’t dump it all at once. You do it in “lifts,” or layers, of about 2 to 3 inches.

Then, you compact it.

You need a vibrating plate compactor for this. Hand tampers are fine for a tiny repair, but for a whole patio? You need the machine. You run that compactor over the gravel until it’s rock hard.

How do you know it’s ready?

It should feel like walking on a concrete sidewalk. If you step on it and leave a footprint, keep compacting. This layer distributes the weight. When you park your truck on the driveway, the pavers transfer that load to the base. If the base moves, the pavers sink. It’s simple physics, but it’s often overlooked.

The Screeding Process

Once your base is solid as a rock, you need a way to smooth out the surface so the pavers sit flat. This is where bedding sand comes in.

This layer is usually coarse concrete sand. You want a consistent depth, usually about 1 inch. To get this perfect, installers use “screed rails”—basically pipes or straight boards—and drag a straight edge across them to level the sand.

A crucial tip: Do not compact this sand.

The sand needs to remain loose so that when you eventually set the pavers and tamp them down, the sand pushes up slightly into the joints (the spaces between the bricks) to lock them in place. If you compact it beforehand, you lose that locking mechanism.

Also, don’t use stone dust or limestone screenings if you can help it. They trap moisture, which is less of an issue here in the dry desert, but they also break down and turn into a mushy paste over time. Stick to sharp, washed concrete sand.

Laying the Pavers: The Fun Part

Finally, the part that actually looks like progress! Laying the pavers is satisfying, but there is a technique to it. You don’t just slide them into place.

If you slide a paver across the sand, you ruin that perfectly screeded surface you just spent an hour creating. instead, use the “click and drop” method. hold the paver slightly above the spot, align the edge against the previous paver, and let it drop straight down. You want them tight, but not forced. Most pavers have little “spacer bars” on the sides to ensure the gap is consistent.

Mixing the Pallets

Here is a pro tip that separates the rookies from the veterans. When you order pallets of pavers—whether it’s Belgard, Tremron, or another brand—there can be slight color variations between pallets. It happens during the manufacturing process.

If you use all of Pallet A, then switch to Pallet B, you might see a distinct line where the color shifts slightly. It looks like a patchwork quilt, and not in a cool way.

- The Fix: Open two or three pallets at once and pull from them randomly. This blends the colors naturally so any variation looks intentional and artistic.

Keeping It Together: Edge Restraints

Imagine you have a group of people standing on a bus. If the bus turns and there are no walls, everyone falls off, right? Your patio is the same. Without something holding the edges, the pavers on the perimeter will slowly drift away into your lawn or flowerbed. once the edges loosen, the middle loosens, and the whole thing falls apart.

You have a few options here:

- Plastic Edging: It’s cheap and easy. You spike it into the ground. It works okay, but in the Gilbert heat, plastic can warp and become brittle over time.

- Concrete Bond Beam: This is often the superior choice for our climate. It involves troweling a wedge of concrete along the hidden edge of the pavers below the grass line. It creates a solid, immovable barrier.

The Finishing Touches: Sand and Seal

So, the bricks are down, the edge is secured. Are we done? Not quite. You have to fill the joints.

In the old days, we just swept in regular sand. But regular sand washes out in the rain and blows away in the wind. Plus, ants love to build condos in it. And let’s be honest, nobody wants an ant farm in their patio.

Polymeric Sand: The Game Changer

This stuff is like magic. It’s sand mixed with a polymer (basically a glue) that activates with water. When it dries, it becomes hard—almost like grout, but it remains flexible enough to handle slight ground movement without cracking.

| Feature | Regular Sand | Polymeric Sand |

|---|---|---|

| Cost | Very Cheap | Moderate |

| Durability | Low (Washes out) | High (Stays put) |

| Weed Prevention | Poor | Excellent |

| Insect Resistance | Poor | Excellent |

Applying Polymeric Sand:

You sweep it into the cracks, then run the plate compactor over the pavers (with a protective pad so you don’t scratch them!). This vibrates the sand deep into the joints. Sweep it again. Compact it again.

Then, you have to blow off every single speck of dust from the surface before you wet it. If you leave dust on the surface and get it wet, you will have a hazy, glued-on mess that is a nightmare to clean.

Sealing: Is It Necessary?

Homeowners ask us this all the time. “Do I really need to seal my pavers?”

Technically? No. The patio won’t fall apart if you don’t. But visually? Absolutely.

Think of the Arizona sun. It bleaches everything. Your car paint, your patio furniture, and yes, your pavers. A good quality sealer does two things:

- UV Protection: It stops the colors from fading.

- Stain Resistance: If you drop a burger or spill a glass of wine, unsealed concrete pavers soak that up instantly. Sealed pavers give you time to wipe it up.

You can choose a “wet look” to make the colors pop, or a “natural look” that is invisible but protective.

Why Hiring a Pro Often Saves Money

I know, I know. We all love a good DIY project. And if you are handy and have a strong back, you can certainly tackle a small walkway. But for larger driveways or patios, the margin for error is slim.

When you factor in the cost of renting an excavator, a bobcat, a plate compactor, and a masonry saw, plus the cost of materials and the sheer physical toll on your body—the savings start to shrink. And that doesn’t include the cost of fixing it two years later if the base wasn’t compacted properly.

Professional installers have the crews to knock out the excavation in a day, the laser levels to ensure perfect drainage, and the experience to handle the tricky cuts around pillars and corners.

Ready to Transform Your Yard?

Getting a paver project right requires a mix of art and engineering. It’s about fighting the soil, managing the water, and creating something that looks beautiful for decades. When it’s done right, it adds massive curb appeal and usable space to your home.

If you are in Gilbert or the surrounding area and want to skip the back-breaking labor and guesswork, we are here to help. We know the soil, we know the climate, and we know how to build hardscapes that last.

Let’s get your project started.

Call us today at 480-534-9680

Or click here to Request a Free Quote